We must explain to you how all seds this mistakens idea off denouncing pleasures and praising pain was born and I will give you a completed accounts of the system and expound.

+0989 7876 9865 9

info@example.com

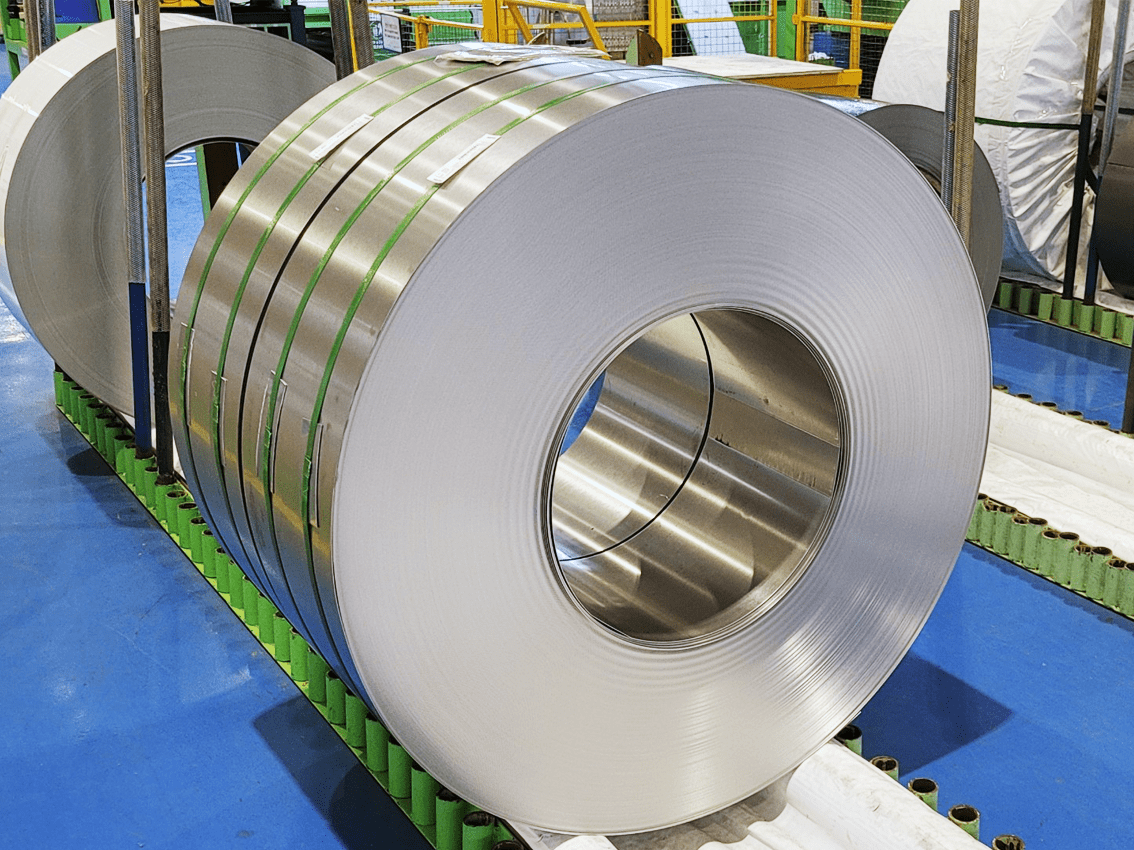

recent years, the demand for stainless steel has been increasing, as a leading company in the production of chromium-based stainless steel with absolute corrosion resistance, high formability with low carbon content, perfect gloss, stable and competitive prices… We are proud of our ability to meet the diverse needs of customers from many different fields such as construction, kitchen equipment, auto parts, electronic components…

The production process of stainless steel (or inox) goes through 5 main stages: Preparation of input materials – Melting – Hot rolling – Annealing and pickling system – Finishing the finished product. In which, the annealing and pickling process helps restore the material properties by heat treatment to stabilize the steel crystal structures that have been deformed or displaced during the rolling process. After that, the product is passed through a mixture of cleaning acids and cleaned with high pressure water to remove rust stains. This stage helps remove product defects, and creates a product with perfect physical and mechanical properties. In addition, this step also helps create a thin protective layer (Chromium Oxide) for the product. Stainless steel is a very popular material. The product is applied in most manufacturing and civil industries. Besides, stainless steel also has outstanding aesthetics and durability compared to other materials.