We must explain to you how all seds this mistakens idea off denouncing pleasures and praising pain was born and I will give you a completed accounts of the system and expound.

+0989 7876 9865 9

info@example.com

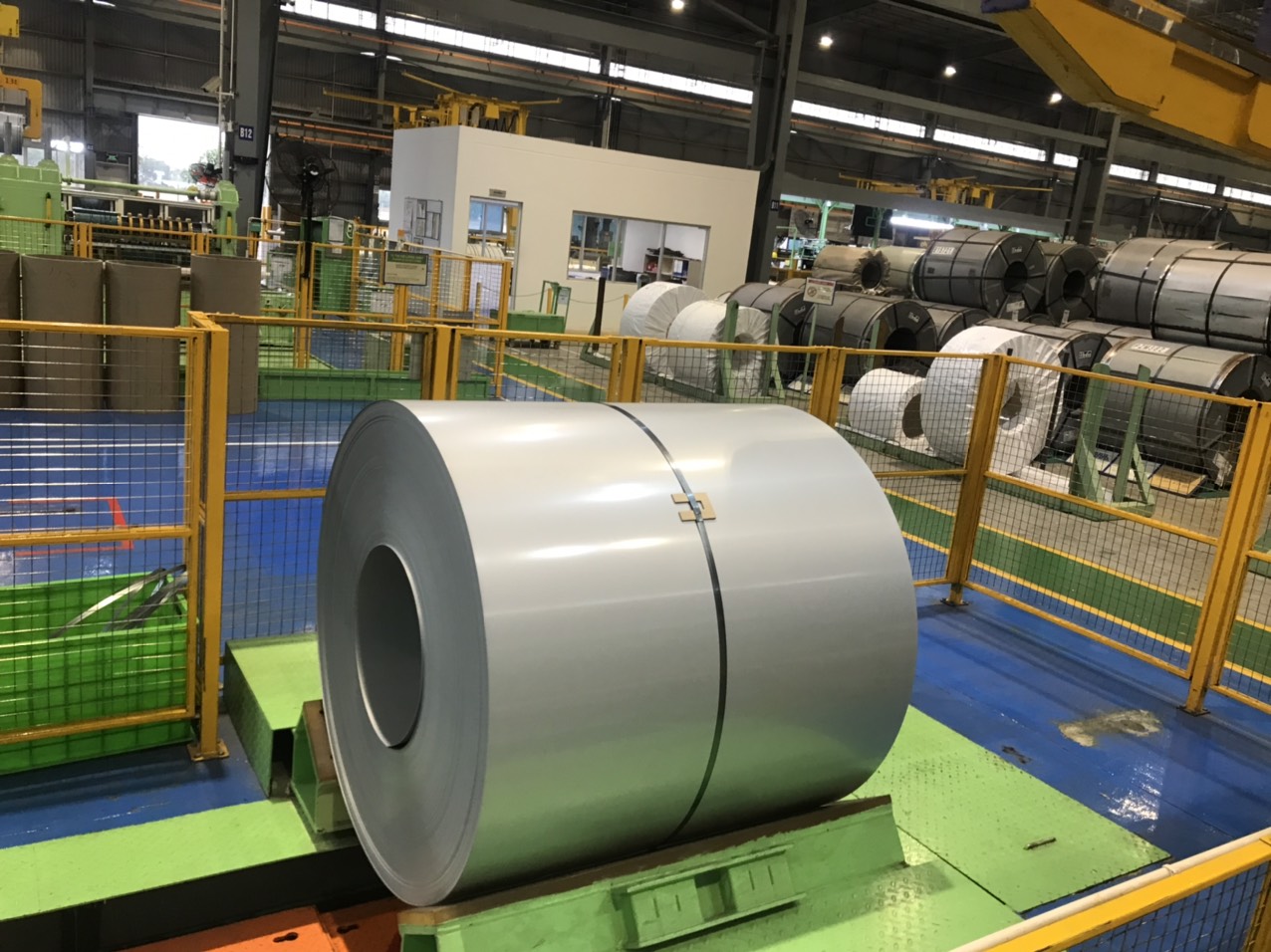

alvanized steel (EG) is one of JSHP’s key products with the commitment to “Protecting the environment and human life”. JFE brand electroplated steel products are increasingly affirming their position in the market. Our goal is to bring high quality products with practical applications, close to human life. We meet the needs of different plating volumes such as: No surface treatment or zinc or Zinc-Nickel alloy coating requirements, Chromium or Chromium-Phosphate treatment, Anti-fingerprint, electrical conductivity, … Requirements related to product application, cut sheet or roll form, packaging requirements including packaging, labels …

Based on hot rolled steel or cold rolled steel, the steel coils are flattened to undergo surface treatment by washing with grease and cleaning. Then they are electroplated in an electrolytic solution and the plating volume is controlled by electricity. Through the electroplating process, the steel surface is chemically treated to improve the surface quality to resist corrosion and have high aesthetics. The surface coating will be re-weighed and carefully inspected before producing the final product.