We must explain to you how all seds this mistakens idea off denouncing pleasures and praising pain was born and I will give you a completed accounts of the system and expound.

+0989 7876 9865 9

info@example.com

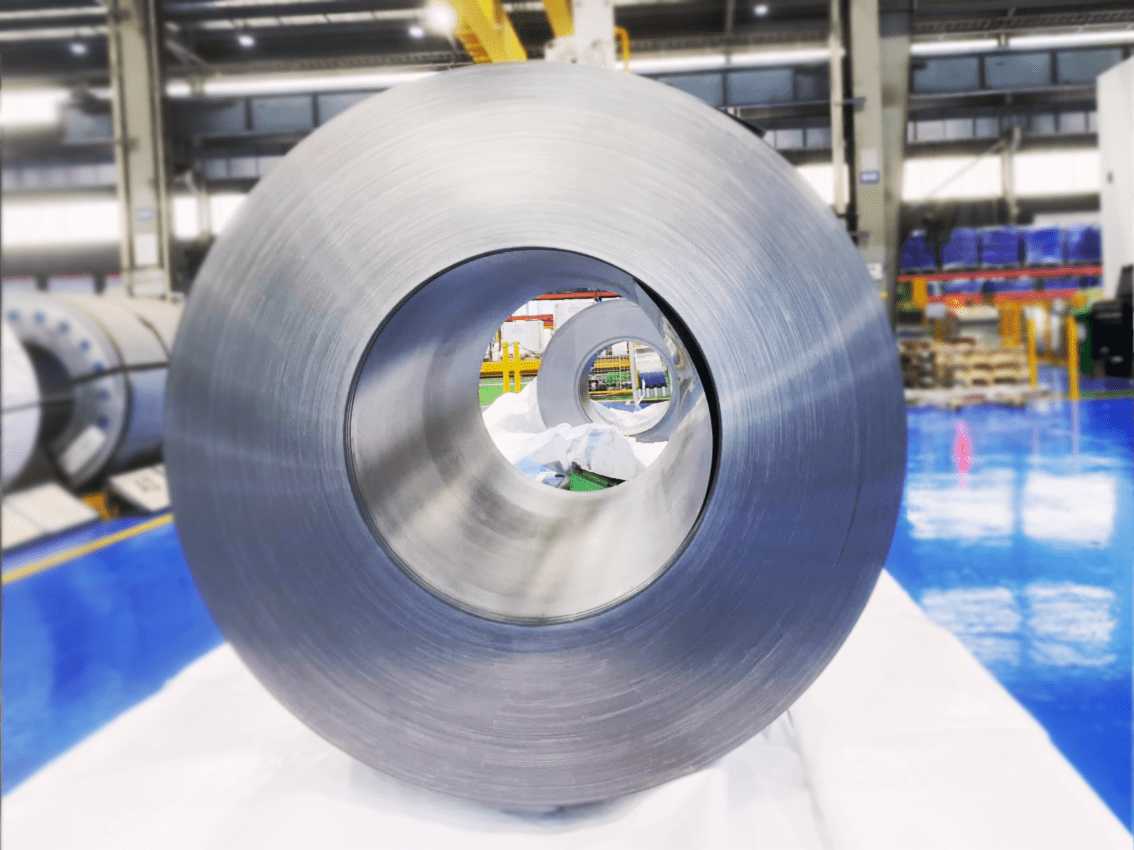

We provide cold rolled sheet/coil products with strict quality control to optimally meet the diverse needs of customers. JSHP provides cold rolled steel products with thickness from 0.25mm-3.2mm with high aesthetic surface, consistent product quality and competitive price. With abundant supply, we provide products based on processing characteristics, hardness requirements and product surface.

Cold rolled steel is hot rolled steel that has been cooled and treated. After cold rolling, it will be rolled again at room temperature to achieve better size and surface quality.

Production process:

The input material is hot-rolled steel coils that will be fed into the surface cleaning and washing line before entering the next stage. The steel coils are fed into the continuous cold rolling line to ensure the steel thickness and steel surface, then fed into the batch annealing line and the continuous annealing line. JFE uses two annealing technologies to reshape the product depending on the product requirements. The annealed coils will continue to go through the Skinpass (or soft annealing) line to adjust the mechanical properties, increase the toughness of the product and finish the steel surface. Finally, the steel coils are unrolled into steel strips according to customer requirements and rolled into steel coils or cut into sheets to produce the final product.